High-volume manufacturing demands maximum throughput and consistent quality with minimal downtime. Leveraging four decades of thin film process technology, Dynavac develops innovative inline deposition systems that bring flawless efficiency to your production operations.

Inline Deposition Systems

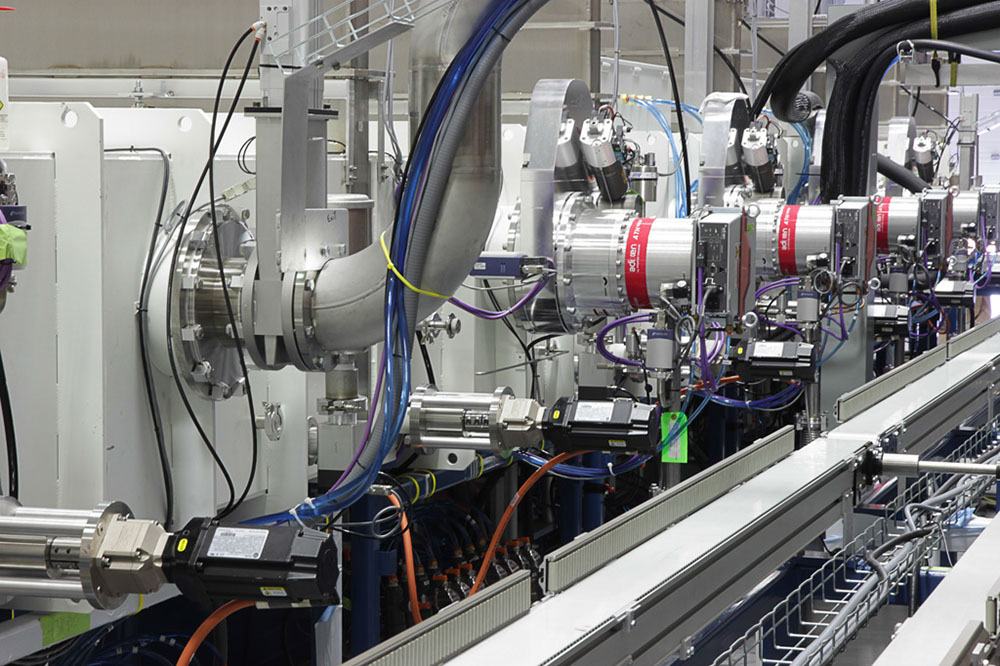

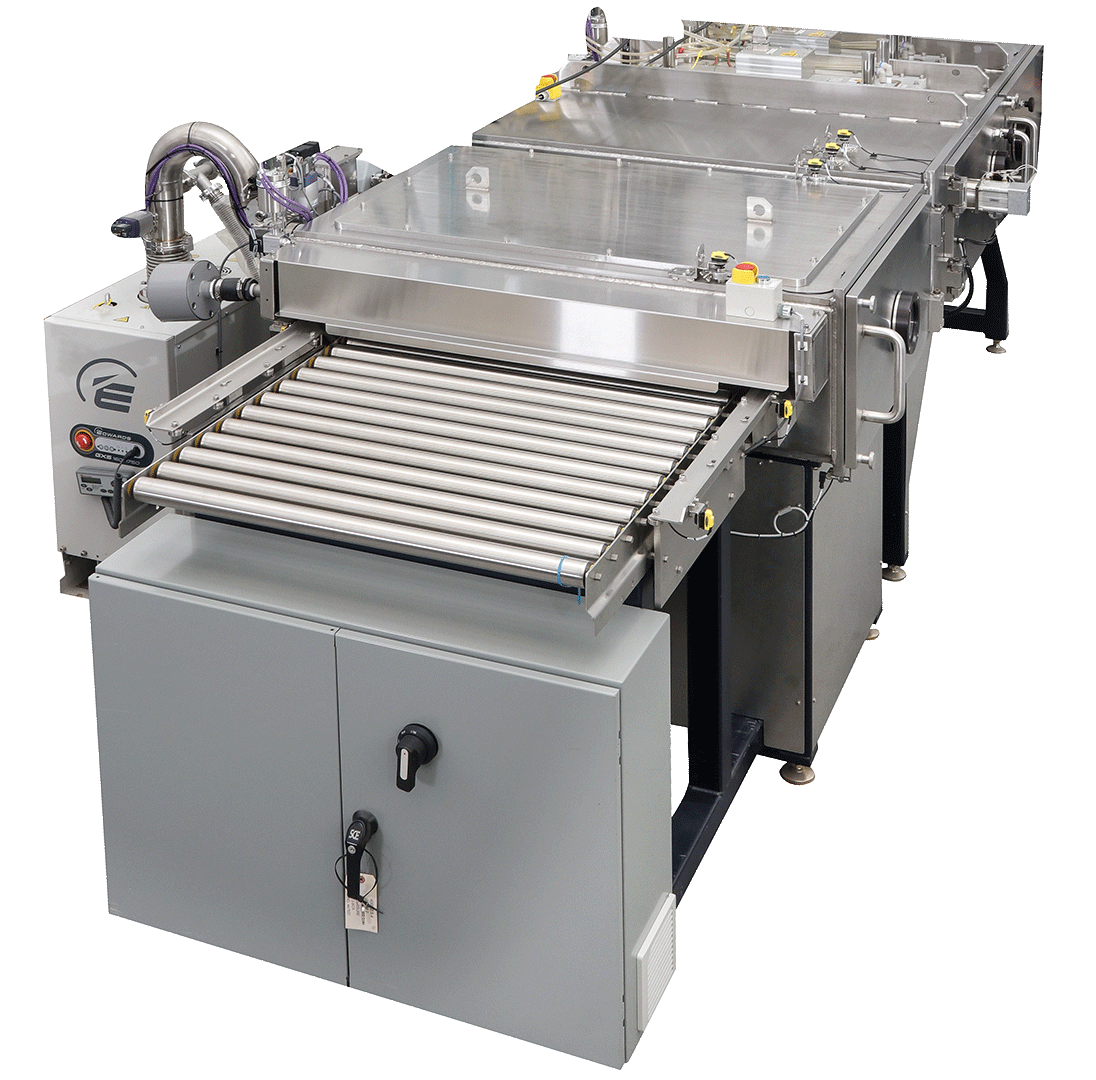

Inline vacuum coating systems for continuous production

System highlights

- Modular vacuum chambers for scalability

- Sputtering, evaporation, or PECVD processes

- Custom-engineered part handling fixtures

- Wide range of pre- and post-deposition processes

- Automated transport systems

- Integrated control systems for complete automation of production sequence

Inline coating applications

- Anti-reflective coatings

- Transparent conductive-oxide coatings

- Substrate metalization

- EMI shielding coatings

- Decorative coatings

- Automotive wheel PVD chrome

- Substrate pre-post treatments (plasma and thermal)

Resources

Thin Film

Thin FilmInline PVD Systems Datasheet

Dynavac has been designing, manufacturing and supporting thin film deposition systems for over 30 years. Our customers are in a wide range of industries, but they share the same expectation: top-quality performance and consistent results, process after process, year after year.

Thin Film

Thin FilmDynavac Announces Partnership with Winona PVD Coatings

Hingham, MA- February 22, 2016. Dynavac, a leader in the manufacturer of thin film deposition systems, is pleased to announce that it has entered into an exclusive supply agreement with Winona PVD Coatings, LLC of Warsaw, Indiana, to produce Inline Production Systems to support growing demand for its G-Chrome deposition process.