Dynavac designs and builds PVD and PE-CVD systems for many applications and markets. We work closely with you to choose the thin film deposition components—from chambers through to control systems—that together meet your most demanding coating needs.

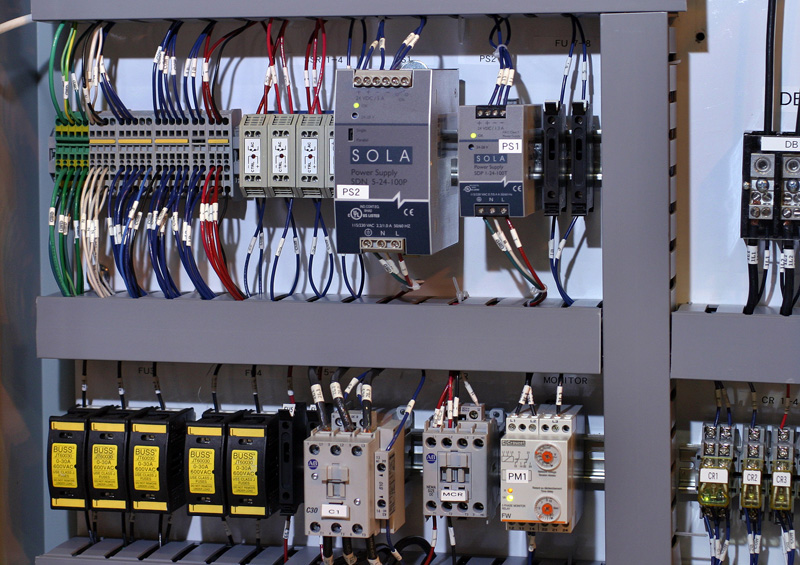

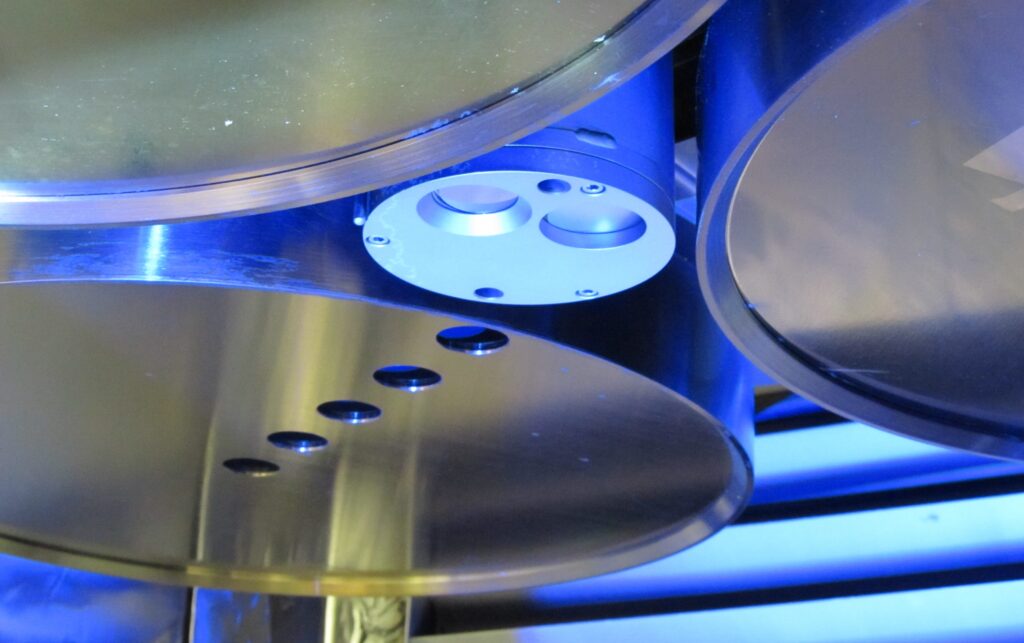

See the wide range of vacuum chambers, sputtering sources, substrate tool and heating, and control systems that Dynavac uses to build high-performance, high reliability thin film deposition systems for a wide variety of coating applications.