At Dynavac, we design and manufacture our systems to the highest standards. Our world-class engineering team’s expertise spans process engineering, mechanical and electrical engineering, and software development. Together with our fabrication experts, we have the competencies to develop complex high-vacuum systems from concept to commissioning.

Our highly skilled employees are vital to the company’s growth and to our commitment to manufacturing in New England. We constantly hire, train, and retain staff dedicated to delivering the very best systems to our customers.

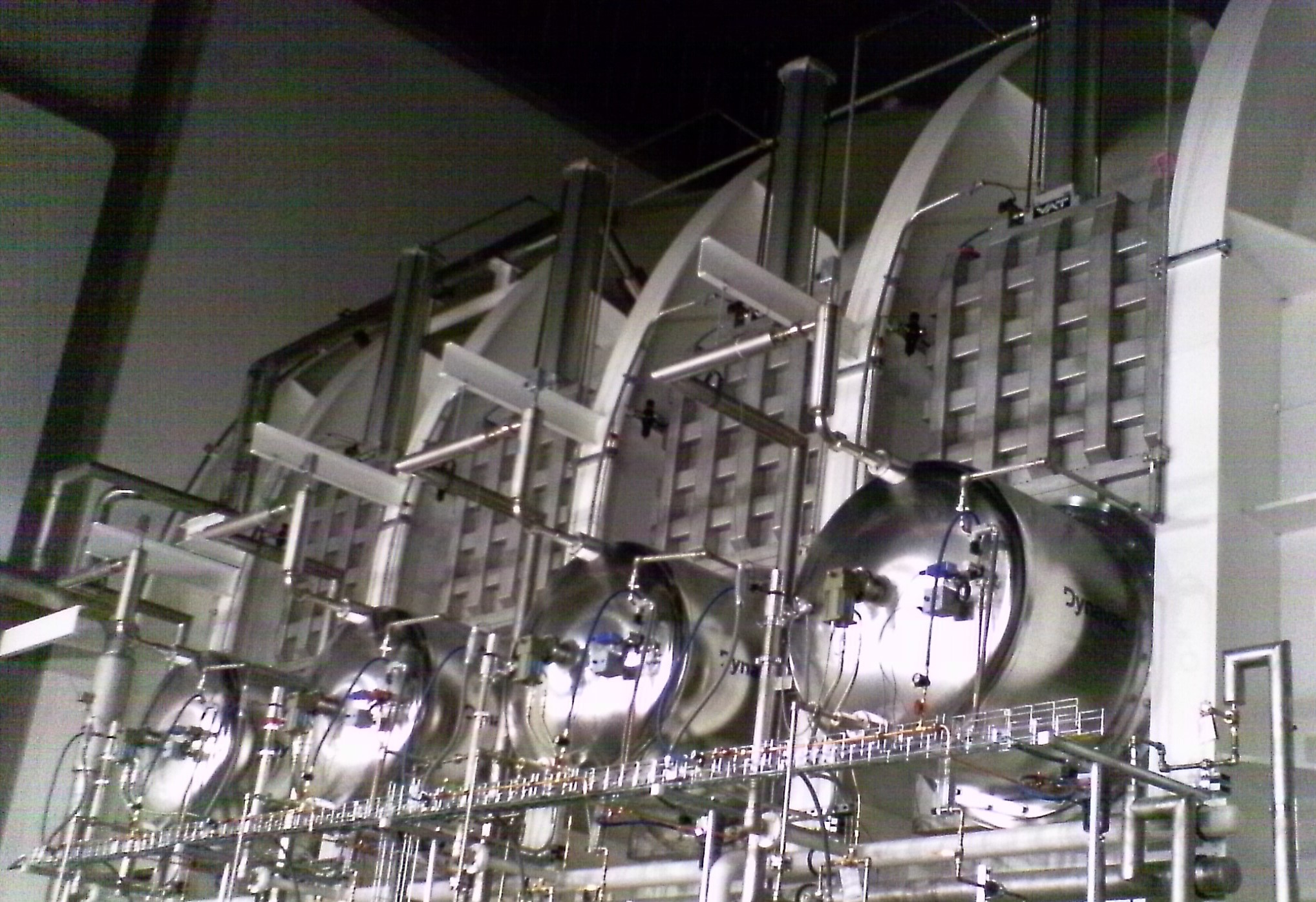

We have over 62,000 square feet in Hingham and Rockland Massachusetts. The Hingham facility serves as the company’s headquarters and houses engineering, business development, and advanced manufacturing. Hingham is also used for system integration and test, light manufacturing, our thin film application lab, and R&D activities. The Rockland facility features high-bay space and overhead cranes to build the very largest systems and components and has dedicated space for system assembly and test.

Dynavac continues to make substantial investments in capital equipment to expand capacity and streamline business processes. A six-axis robotic laser cutting system is at the center of our vacuum chamber manufacturing process, reducing manufacturing costs and lead times. Our engineers use the latest CADCAM tools.

Dynavac operates under ISO-9001 quality assurance standards. Operations are supported by a fully integrated ERP system.

Our continuing investment in facilities, workforce, and equipment strengthens Dynavac’s leadership in production capacity, methods, and quality. Dynavac is committed to providing the very best design, manufacturing, test, and support capabilities in our industry to meet customers’ increasingly sophisticated needs.