Hingham, MA and Ft Collins, CO September 13, 2022: Dynavac, a leading provider of custom high-vacuum systems and equipment is pleased to participate in Colorado State University’s supersonic research. Dynavac donated a 1.5-meter vacuum chamber which serves as a main component of the supersonic wind-tunnel under development at CSU. The facility will be used for researching supersonic propulsion, including ignition inside a supersonic stream, flame holding, and flame stabilization.

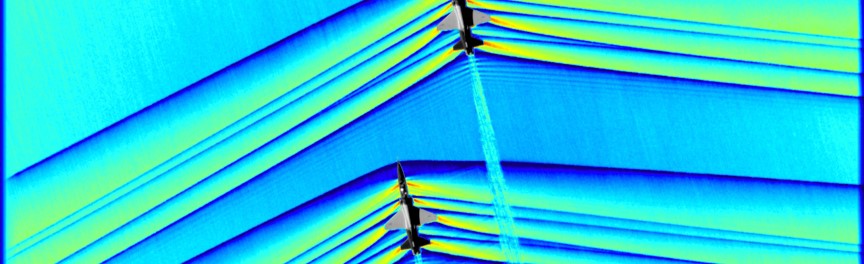

The wind tunnel will generate high-speed flows reaching Mach 2.5. The in-draft design is based on the energy stored as a pressure difference between a low-pressure chamber and the outside atmosphere. During operation, air flowing from the atmosphere through a converging-diverging nozzle (like that of a rocket engine), accelerates to supersonic speeds. The experiment is conducted in a test section placed after the nozzle, and the high-velocity airflow than comes to rest in the low-pressure chamber. The capacity of the Dynavac vacuum chamber allows several hundred milliseconds of supersonic conditions, typical of most existing supersonic wind tunnels. The CSU system is a modular design that can be adapted for higher Mach numbers in the future.

Compared to typical blowdown supersonic tunnels, which employ a high-pressure tank at the inlet, the indraft tunnel offers several key advantages:

- Low-cost due to its simplicity

- Constant stagnation temperature and pressure throughout the test time

- Lower noise levels

- Increased safety of vacuum operation (no high-pressure regulators and fast response relief values required)

Dynavac is honored to contribute to this exciting project and the research at Colorado State University.

Image credit: NASA