High-volume manufacturing demands maximum throughput and consistent quality with minimal downtime. Leveraging four decades of thin film process technology, Dynavac develops innovative inline deposition systems that bring flawless efficiency to your production operations.

Inline Deposition Systems

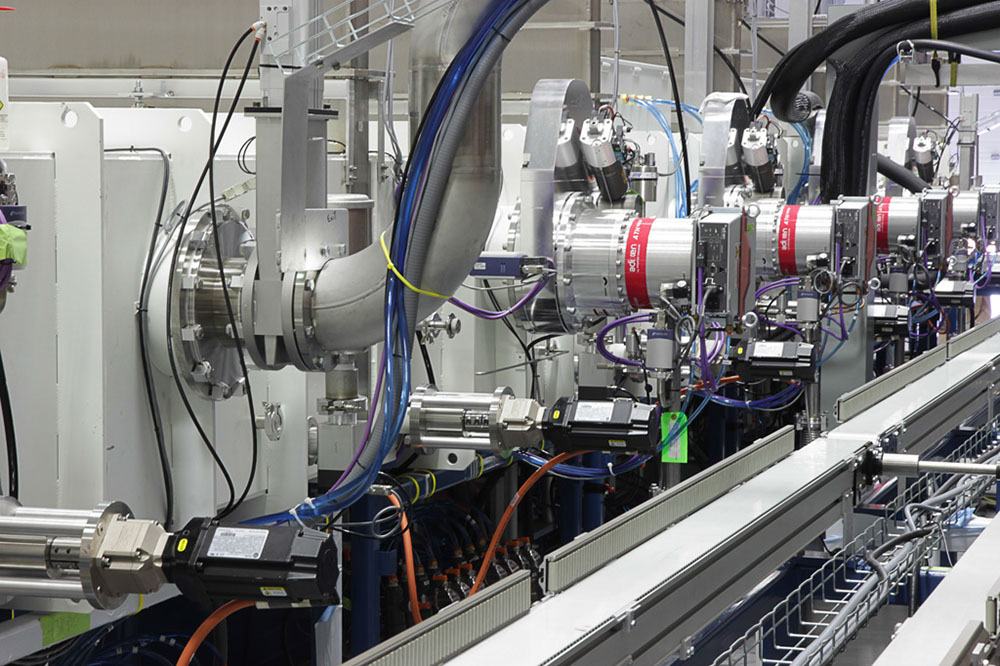

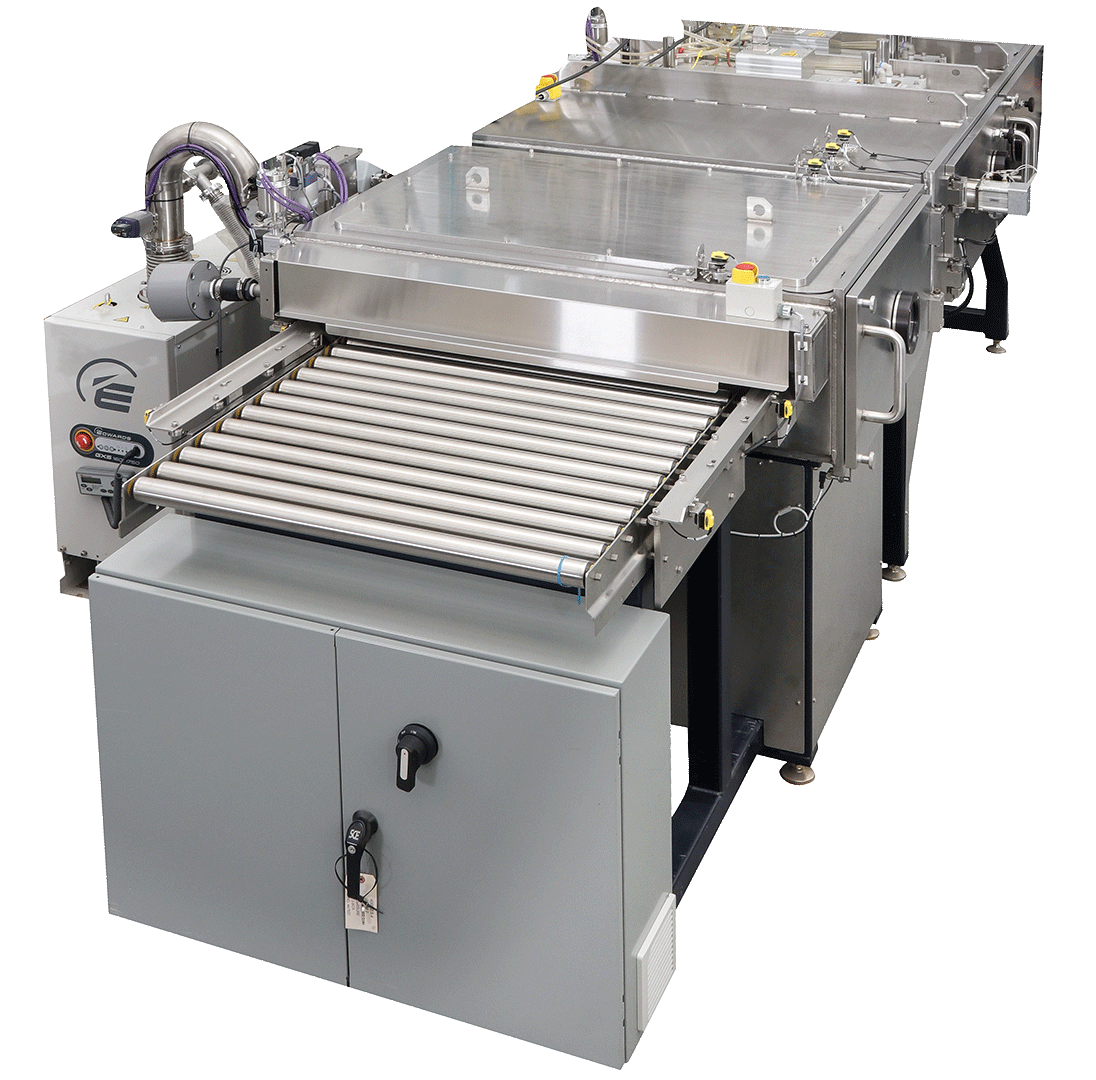

Inline vacuum coating systems for continuous production

Built to your requirements

Dynavac’s inline systems enable continuous deposition of thin films onto glass, plastic, or metal across a variety of applications. Whether you’re producing automotive parts or display panels, our engineers work with you to determine a process and system that help you attain your desired film properties while optimizing productivity and lowering costs.

All of our systems are backed by Dynavac’s outstanding track record of building reliable, high-performance equipment that stands the test of time.