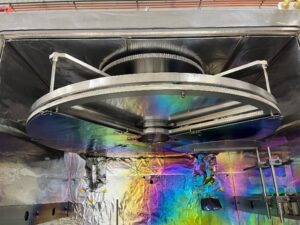

Dynavac’s unique mask-indexing design enables coating on selected portions of the substrate holder in a single batch cycle without breaking vacuum.

A segmented circular mask divided into sections exposes selected parts of the substrate holder, coating individual sections of the substrate holder with different coating stacks within a single pump down. For example with a mask made of quadrants, four separate processes can be run in a single pumpdown. Need more parts to be coated in a single quadrant? Simply remove a second quadrant mask and double the coated substrates.

A circular mask attached to the main rotary hub rotates with the substrate rotation system. The “wedge lock” assembly that locks the mask in position is disengaged and rotated to a new position exposing a different section of the substrate holder. Indexing of the mask is done in-situ while the system is under vacuum, enabling deposition of various films stacks onto different substrates.

This mask indexing works with single or planetary substrate rotation.

This setup is ideal for:

- Relatively short process runs with long system pump down times

- R&D coating runs with several overlaying films stacks

- Coating different substrates with different stacks under one pump down.

Contact us to learn more about this design and Dynavac’s full range of thin film deposition solutions.

Dynavac’s indexed mask substrate holder