The Dynavac Applications Laboratory helps our customers develop and test demanding coating processes in a real-world setting before committing to a large capital investment. Dynavac’s nearly forty years’ expertise in thin film technology helps you reduce risk by optimizing the full system design.

Application Lab

Take advantage of our process and equipment expertise for your next thin film deposition system before committing capital.

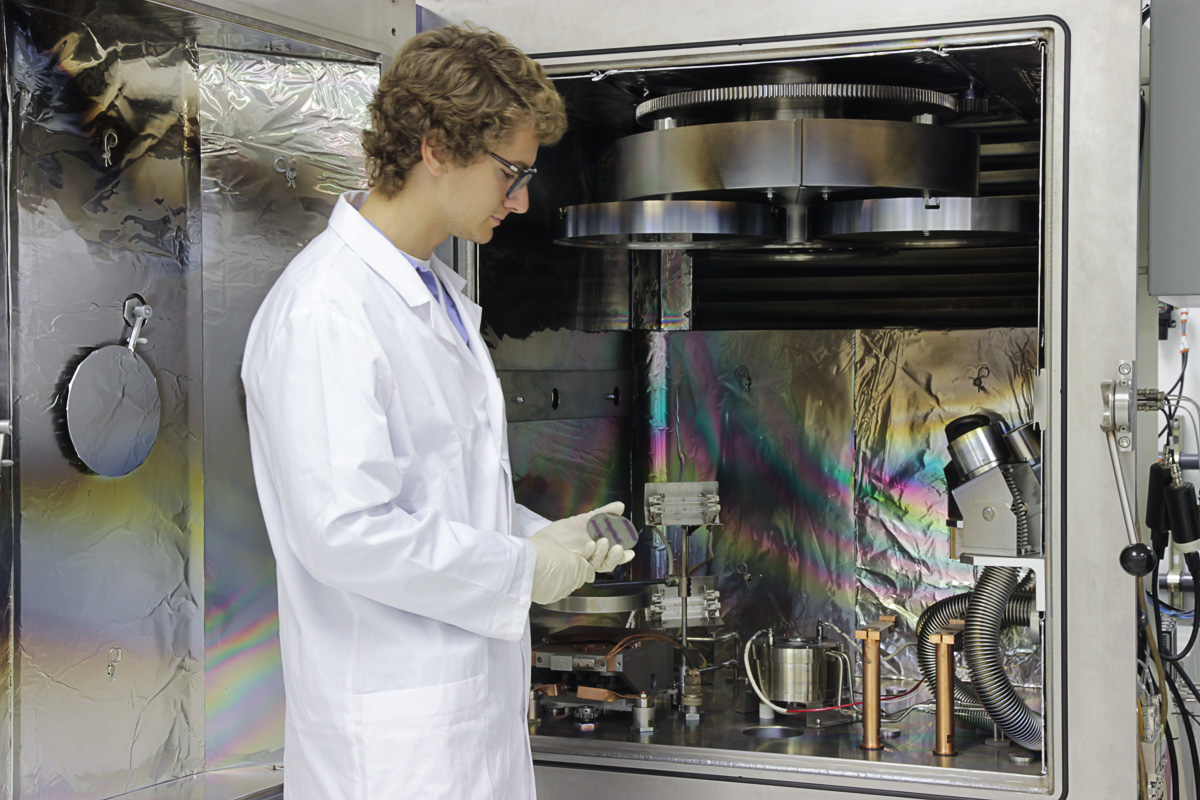

Ramya Chandrasekaran, PhD, heads our work in the 1,700 square-foot Application Lab located in our Hingham, Massachusetts design and manufacturing center. The lab helps customers evaluate a wide range of thin-film issues, including:

- New applications and processes

- Material characterization

- Substrate surface pretreatment

- Film and substrate temperature and thermal load analysis

- Outgassing properties, wear and tear, and lifetime efficacies of parts and components

- Reliability, throughput, and cost of ownership

The lab features our Hyperion Optical Coating System outfitted to support a variety of thin film processes:

- Thermal and electron beam evaporation

- Magnetron sputtering

- Filament evaporation

A full suite of process control and metrology instrumentation is dedicated to process development, and includes:

- Dynavac Spectrum Pro Broadband Optical Monitoring System

- Quartz crystal monitoring

- Residual gas analyzer

- Surface profilometer

- Spectrophotometer

- Optical microscope