New vacuum chamber will help develop propulsion for CubeSats

Hingham, MA and San Luis Obispo, CA. September 9, 2022 – Dynavac is pleased to announce the installation and commissioning of a turnkey space simulation system at California Polytechnic State University San Luis Obispo (Cal Poly). This single system is a dual-purpose chamber, enabling both electric propulsion and thermal vacuum testing.

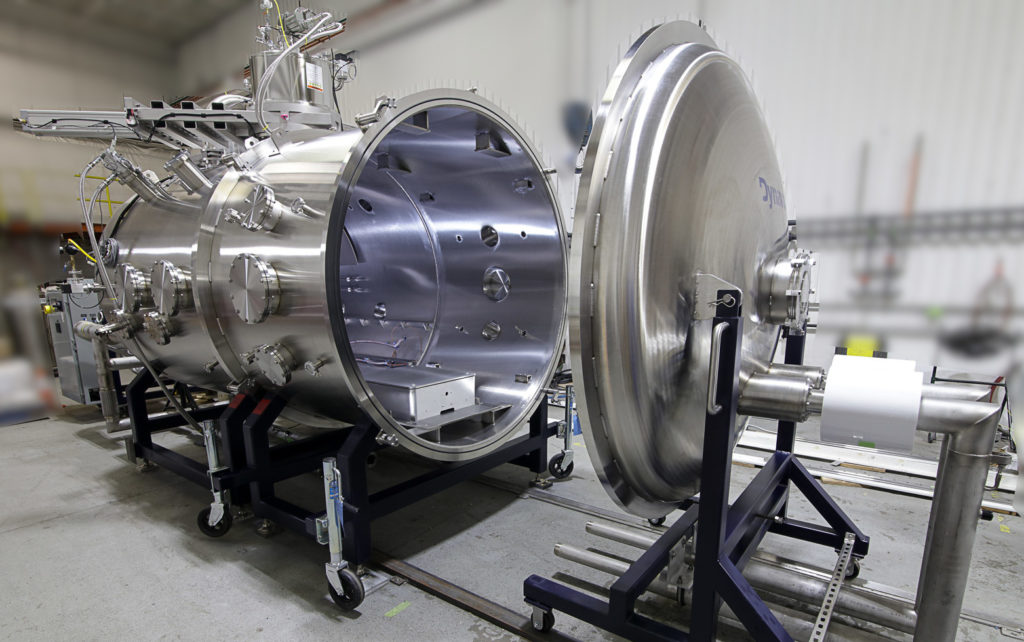

The modular 6 x 10-foot chamber is equipped with multiple pumping components to provide a test environment representative of the high vacuum levels encountered in spaceflight. The electric propulsion test (EPT) configuration allows for xenon and argon propellant thrusters to be tested at mass flowrates of 0.1 to 10 mg/second.

Dual EPT/TVAC system at Cal Poly

Maintaining space-like conditions under these mass flow rates required special attention to the pumping system design. Dynavac’s Director of Technology, Ramya Chandrasekaran, Ph.D. said “We designed several internal cold arrays cooled to 20 Kelvin (~-250°C) and positioned them to enable pumping condensable propulsion gases. Additionally, a plasma beam dump target cooled with liquid nitrogen absorbs the energy of the propellant to hold the required vacuum and thermal levels. We also built a vibration isolation platform for the propulsion engine to function under expected operational conditions on a spacecraft.”

The system can be converted to thermal vacuum (TVAC) testing by installing a shroud and platen. Dynavac used its forty years’ experience in the chamber and subsystem design to provide high performance in both EPT and TVAC testing configurations. A Dynavac gaseous nitrogen thermal conditioning unit provides thermal control over an operating range of -180°C to 150°C.

Cal Poly has a long history in the development of innovative satellite technology, including being the co-creator of the CubeSat platform. Today Cal Poly is very active in the research, development, and deployment of spacecraft. This dual-purpose chamber, located in the Space Propulsion Facility at the Advanced Technology Lab, serves an important role in advancing aerospace technology.

System undergoing final integration at Dynavac

“The dual-purpose TVAC chamber is the cornerstone of the new Space Propulsion Facility, providing a state-of-the-art capability and flexibility that will amplify Cal Poly’s technical development and testing of innovative satellites and propulsion systems,” said Cole Saucier, a lecturer in the Aerospace Engineering Department at Cal Poly.

The new vacuum chamber will allow researchers to test and develop propulsion for CubeSats, providing greater control of the satellites for space exploration. Currently, most CubeSats cannot be controlled in space, and propulsion and maneuverability are often viewed as the next major steps in CubeSat technology.

About Dynavac

Dynavac designs, manufactures, and installs high-vacuum systems for space simulation, thin film deposition, and specialty applications. The company is recognized for its expertise in high vacuum technology, system and component design, and field support. Dynavac manufactures its systems in Hingham and Pembroke, MA, and serves customers around the world.

With nearly forty years’ experience in the aerospace industry, Dynavac proudly supports customers engaged in some of the most exciting and demanding space programs. Visit dynavac.com/solutions/space-simulation/ to learn more.

About Cal Poly

Since 1901, Learn by Doing has always been Cal Poly’s core philosophy. It’s a deliberate process in which students, from day one, acquire knowledge and skills through active engagement and self-reflection inside the classroom and beyond it. Experiences are a critical part of the curriculum, which shows students how theory combines with application and prepares them to use their knowledge to solve the world’s challenges. The result of this experience is that Cal Poly graduates are ready, from day one, to make an immediate impact on the world around them in their careers and throughout the rest of their lives.

The newly instituted Space Propulsion Facility provides access to thermal vacuum capabilities for satellite and electric propulsion testing with chamber base pressures reaching 10-7 Torr and temperature ranges of -180C to 150C.

Read more here…