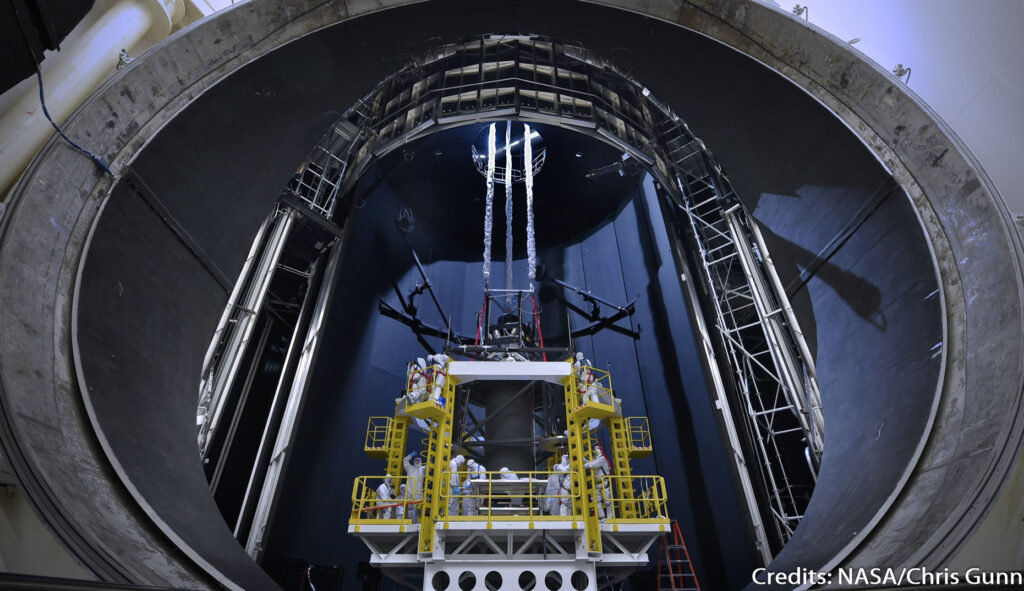

Challenge: To conduct deep space testing for its new James Webb Space Telescope (JWST), NASA needed to upgrade its historic Chamber A at the Johnson Space Center that was famously used to test Apollo space craft. The JWST is a large infrared telescope with a 6.5m primary mirror set to launch in 2018 to replace the Hubble Telescope. Testing the JWST required the massive 45 foot diameter x 65 ft high chamber to reach and hold temperatures of 30K (-405 °F). Never before had this been a been attempted for this large of a chamber.

Solution: To develop this unprecedented Gaseous Helium (GHe) shroud system, NASA and its primary contractor, Jacobs, turned to Dynavac- the expert in thermal cryogenic engineering and manufacturing. Dynavac fabricated and installed both LN2 (80 K) and gaseous helium cooled (20 K) shrouds. The helium gas generated from the helium refrigeration system passes through extruded tubing to create the thermal environment. The interior shroud system, fabricated from aluminum sheet and I beams, was constructed from panels approximately 12 ft wide and 40 ft long. These had to be painted on one side with special high optical absorptivity/emissivity black paint.

Solution: To develop this unprecedented Gaseous Helium (GHe) shroud system, NASA and its primary contractor, Jacobs, turned to Dynavac- the expert in thermal cryogenic engineering and manufacturing. Dynavac fabricated and installed both LN2 (80 K) and gaseous helium cooled (20 K) shrouds. The helium gas generated from the helium refrigeration system passes through extruded tubing to create the thermal environment. The interior shroud system, fabricated from aluminum sheet and I beams, was constructed from panels approximately 12 ft wide and 40 ft long. These had to be painted on one side with special high optical absorptivity/emissivity black paint.

Here’s a NASA update regarding testing the James Webb Pathfinder in Chamber A